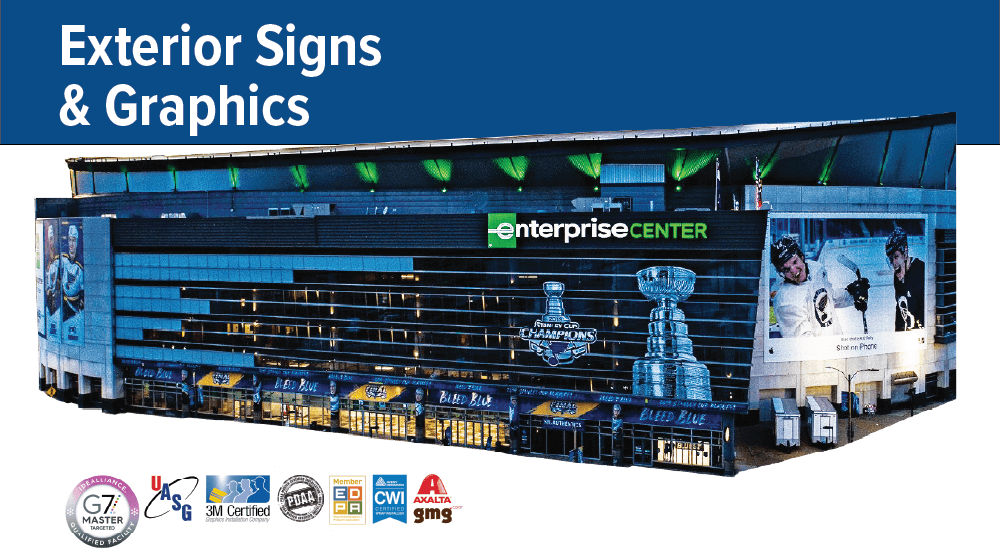

Exterior Signs & Graphics

Our Exterior Signs & Graphics department is second to none.

Since 1982, Craftsmen has been bringing ideas to life. Our full-service teams print and install exterior signs and graphics using their depth of knowledge and state-of-the-art software and production machines.

We produce all of our custom graphics in a quality-controlled color environment to ensure integrity across the board. Our history of graphic success proves that we are the leader in the industry. We focus heavily on our client’s needs to ensure your space, venue, or stadium looks exactly the way you hoped.

Craftsmen is your one-stop shop to get your 'Ideation to Creation. FAST!'

Contact us to find out how Craftsmen

can turn your branding dream into a reality

or Call Today 800.373.3575

Full-Service In-House Graphics Department

"If you want to build the impossible, Craftsmen has the tools and talent. They are more like a Venture partner than a builder."

Founder & CEO

Magicbox

Magicbox

"Craftsmen, hands down, had the best ideas, best drawings. They were as passionate about the project as I was. I don't know why anyone would go anywhere else."

PGA Tour Technician

TaylorMade

TaylorMade

"High caliber work, great crew of talented workers who come up with creative solutions and are easy to work with, overall great partners."

Creative Director

Dairy Farmers of America

Dairy Farmers of America

"The team at Craftsmen is top notch and they always get the job done no matter the deadline. I consider them an extension of our team - a true partner!"

Executive Director

Clayco

Clayco

Exterior Signs & Graphics

CUSTOM OUTDOOR SIGNAGE BY CRAFTSMEN INDUSTRIES

Our custom outdoor signage solutions help businesses stand out with high-quality, weather-resistant materials and precision craftsmanship. As a 3M™ Certified Graphics Installation Company and proud member of PDAA and UASG, we ensure expert installation and durability.

From storefront signs to fleet graphics, we create impactful visuals that enhance brand visibility and customer engagement. Elevate your brand presence with professionally designed and installed signage solutions.

Make a lasting impression with exterior signs & graphics from Craftsmen Industries.

Why Choose Craftsmen Industries?

Craftsmen Industries combines expert craftsmanship, cutting-edge technology, and industry certifications to deliver premium exterior signs and graphics. Our PDAA and UASG certifications guarantee the highest installation standards, ensuring durability and vibrant displays. With over 40 years of experience, we offer tailored solutions to meet your business’s unique branding needs.

- 3M™ Certified Installation: Ensures precision, durability, and long-lasting graphics.

- High-Quality Materials: Weather-resistant and UV-protected for maximum lifespan.

- Custom Design & Fabrication: Fully tailored solutions to match brand identity.

- Nationwide Service: Professional installation available across the U.S.

- Advanced Printing Technology: High-resolution graphics with fade-resistant finishes.

Transform Your Brand with Custom Outdoor Graphics

Enhance your business’s visibility with stunning, long-lasting exterior signs and graphics. Let Craftsmen Industries help you design and install signage that captures attention and strengthens brand recognition.

What Are Exterior Signs and Graphics?

Exterior signs and graphics are visual communication tools designed for outdoor use, helping businesses attract customers, convey messages, and enhance brand identity. These include storefront signage, banners, vehicle wraps, and monument signs, all built for durability and weather resistance. Businesses use exterior signage to communicate promotions, display their logos, guide customers, and create a recognizable brand presence.

Materials vary based on the intended purpose, location, and weather conditions. Common options include aluminum, acrylic, PVC, and vinyl, each offering unique advantages. Aluminum signs are rust-resistant and ideal for long-term use, while vinyl graphics provide a flexible and cost-effective branding solution. Advanced printing and lamination techniques ensure colors remain vibrant even after prolonged exposure to sunlight and harsh weather.

Why Are Exterior Signs and Graphics Important for Businesses?

Outdoor signage is crucial for brand recognition, customer attraction, and business credibility. A well-designed sign improves visibility, directs traffic, and reinforces brand identity. Studies show that 68% of consumers believe a business’s signage reflects the quality of its products and services. Investing in high-quality exterior graphics ensures a strong first impression and increased foot traffic.

Businesses in retail, hospitality, healthcare, and corporate sectors rely on outdoor signage for effective marketing and communication. A restaurant might use illuminated channel letter signs for visibility at night, while a corporate office may opt for monument signage to reinforce professionalism. Fleet graphics turn company vehicles into mobile advertisements, generating thousands of impressions daily. The right exterior signage strategy boosts brand recall, attracts new customers, and enhances the customer experience.

Different Types of Outdoor Signs & Graphics

Craftsmen Industries offers a variety of exterior signage solutions, including:

- Channel Letter Signs: 3D illuminated or non-illuminated lettering for storefronts, offering high visibility and a professional look.

- Monument Signs: Ground-level structures made from stone, metal, or acrylic, commonly used for corporate offices, schools, and business parks.

- Pole & Pylon Signs: Tall, freestanding signs with high visibility for roadside businesses like gas stations, shopping centers, and hotels.

- Vehicle Wraps & Fleet Graphics: Full or partial wraps that transform vehicles into mobile billboards, providing continuous advertising.

- Window Graphics & Decals: Vinyl graphics applied to storefront windows to promote sales, reinforce branding, or provide privacy.

- Banners & Flags: Cost-effective and temporary signage solutions, often used for events, promotions, or seasonal advertising.

- Wayfinding & Directional Signs: Essential for guiding visitors in large spaces like hospitals, campuses, and commercial buildings.

Each sign type serves a unique purpose, helping businesses attract attention, convey messages, and increase brand awareness. The choice of signage depends on factors like location, budget, and intended audience. Businesses often combine multiple types for a cohesive branding strategy.

Exterior Signs and Graphics Customization

Craftsmen Industries provides fully customizable exterior signage to match your brand’s unique identity. Customization options include:

- Materials: Acrylic, metal, vinyl, wood, and more, chosen based on durability and aesthetics.

- Lighting: LED, backlit, or non-illuminated options to enhance nighttime visibility.

- Size & Shape: Fully scalable designs that fit storefronts, vehicles, or outdoor landscapes.

- Color & Finish: Vibrant, weather-resistant coatings that prevent fading and maintain brand consistency.

- Installation Methods: Wall-mounted, freestanding, or vehicle-applied solutions for seamless branding integration.

Custom signage ensures your brand stands out while maintaining a professional and cohesive image. Advanced fabrication techniques allow for intricate designs, textured finishes, and unique branding elements. Our team works closely with clients to develop solutions that align with their marketing goals and operational needs.

Materials We Use for Exterior Signs and Graphics

Craftsmen Industries uses high-quality, durable materials designed to withstand outdoor conditions while maintaining a professional appearance. The choice of material depends on factors like weather resistance, longevity, and visual impact. Below are the most commonly used materials for exterior signs and graphics:

|

Material |

Benefits |

Best For |

Lifespan |

|

Aluminum |

Lightweight, rust-resistant, highly durable |

Long-term business signage, real estate signs |

7-10 years |

|

Acrylic |

Glossy finish, UV-stable, weather-resistant |

Logo signs, storefront signage, dimensional letters |

5-8 years |

|

PVC (Polyvinyl Chloride) |

Cost-effective, moisture-resistant, lightweight |

Temporary outdoor signs, promotional signage |

3-5 years |

|

Vinyl |

Flexible, easy to apply, available in various finishes |

Window graphics, vehicle wraps, decals |

3-7 years |

|

Corrugated Plastic (Coroplast) |

Lightweight, waterproof, cost-effective |

Temporary event signage, real estate signs |

1-3 years |

|

Wood |

Natural look, sturdy, customizable |

Rustic-themed business signs, parks, boutique stores |

5-10 years |

|

Stainless Steel |

Elegant, rust-resistant, highly durable |

Corporate signage, luxury business branding |

10+ years |

Choosing the Right Material for Your Sign

The best material for your exterior signs and graphics depends on:

- Longevity needs (short-term vs. permanent signage)

- Weather conditions (humidity, UV exposure, temperature fluctuations)

- Aesthetic preferences (glossy, matte, brushed metal)

- Budget considerations (cost-effective vs. premium materials)

Craftsmen Industries helps you select the perfect material for your outdoor signage needs. Our 3M™ Certified Graphics Installation ensures long-lasting, professional results with every project. Contact us today for a custom consultation and quote!

Frequently Asked Questions

1. How long do exterior signs last?

The lifespan depends on materials and exposure. High-quality outdoor signs can last 5-10 years with proper maintenance. Regular cleaning and protective coatings can further extend durability.

2. Are Craftsmen Industries’ signs weather-resistant?

Yes, we use durable materials and protective coatings to withstand extreme weather conditions. Our signs are designed to resist UV rays, moisture, and temperature fluctuations.

3. Do you offer installation services?

Yes, as a 3M™ Certified Graphics Installation Company, we provide professional installation nationwide. Our expert installers ensure precise placement and secure mounting for long-lasting results.

4. Can signs be customized to match my brand colors?

Absolutely! We use color-matching technology to ensure your signage aligns with your brand identity. Custom finishes and textures are also available for a unique look.

5. What is the turnaround time for custom exterior signage?

Turnaround times vary based on complexity, but most projects take 2-4 weeks from design to installation. Rush services may be available for urgent projects—contact us for details.

Elevate Your Business with High-Impact Exterior Graphics

Stand out from the competition with professionally crafted exterior signs & graphics from Craftsmen Industries. Whether you need a bold storefront sign or fleet graphics for mobile advertising, we deliver high-quality, long-lasting solutions. Contact us today to discuss your signage needs and request a quote.

%202.jpg)