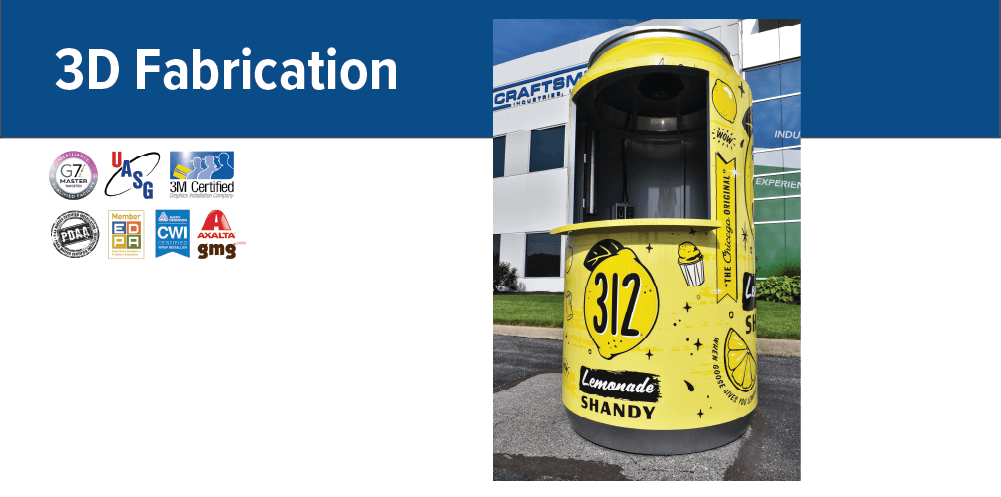

3D Printing

Go Big with our 3D Printing Service

Attract your audience with larger-than-life 3D-printed props. They offer a perfect opportunity for customers to snap a photo to share on social media increasing your impressions.

Our 3D printing service can create large-scale versions of your idea that won't be missed at your event!

Your options are nearly endless - we can 3D print your logo, product, mascot, or whatever you dream up. These 3D pieces are a wow factor at trade shows, product launches, experiential marketing activations, and other special events.

Need some help with a final design? Let's get creative! We have in-house designers that can help with your 3D printing project.

Need a quick turnaround? Our 3D printing technology allows us to create larger-than-life products in a matter of hours!

We also have the capabilities to finish your 3D printed project with sanding, painting, and installation of large-format graphics, so the final product is exactly how you envisioned, all complete within your timeline and budget.

Contact us to find out how Craftsmen

can turn your branding dream into a reality

or Call Today 800.373.3575

Full-Service In-House Graphics Department

Full-Service In-House Graphics Department

"If you want to build the impossible, Craftsmen has the tools and talent. They are more like a Venture partner than a builder."

Founder & CEO

Magicbox

Magicbox

"Craftsmen, hands down, had the best ideas, best drawings. They were as passionate about the project as I was. I don't know why anyone would go anywhere else."

PGA Tour Technician

TaylorMade

TaylorMade

"High caliber work, great crew of talented workers who come up with creative solutions and are easy to work with, overall great partners."

Creative Director

Dairy Farmers of America

Dairy Farmers of America

"The team at Craftsmen is top notch and they always get the job done no matter the deadline. I consider them an extension of our team - a true partner!"

Executive Director

Clayco

Clayco

Request a Quote

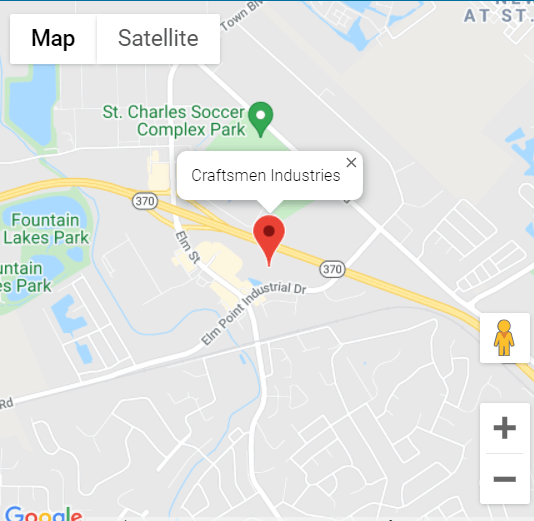

Contact Information

3101 Elm Point Industrial Drive

St. Charles, MO 63301

1.800.373.3575

Contact Us

What is 3D printing?

The creation of a 3D-printed object is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects, it just stacks and fuses layers of material. It’s generally quick, with minimal fixed setup costs, and can create more complex objects than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

Different types of 3D printing:

- Vat Polymerization

- Material Extrusion

- Powder Bed Fusion

- Material Jetting

- Binder Jetting

- Direct Energy Deposition

- Sheet Lamination

What are the benefits of 3D printing?

There are many different types of 3D printing options available, but the benefits of 3D printing will be sure to offer any vertical an advantage. With the unparalleled ability to provide your customers with high levels of accuracy, increased speed-to-market, easy testing, and the ability to create custom specialty parts with lower fabrication costs, it is sure to provide ample reasoning to implement 3D printing into your next project.

Common benefits of 3D printing:

- Flexibility

- Sustainability

- Competitive advantage

- Cost

- Product testing

- Tangible design

- Quality

- Risk Reduction

- Consistency

- Accessibility

- Speed

What materials are used?

With 3D printing being so versatile, the range of materials that can be used is as diverse as the products that come from the process. Each material has its own unique features, strengths, durability, and weaknesses. Making sure that you have the right material for the job you are trying to accomplish is crucial because of the high variance nature of 3D printing. Important factors such as texture, material type, and cost will also need to be considered.

Common materials used in 3D printing:

- Nylon

- Resin

- ABS (Acrylonitrile Butadiene Styrene)

- Gold

- Silver

- PLA (Polylactic Acid)

- Titanium

- Stainless steel

- Ceramics

- HIPS (High Impact Polystyrene)

- PET/PETG (Polyethylene terephthalate)

How long does 3D printing take to complete?

The process of 3D printing will usually start by gathering all the information on the desired object being created. After gathering that information, the creation process of getting said object in hand can take anywhere from 30 minutes to 7 days or more. There are many different factors in the 3D printing process that will dictate the length it takes to create a part. A few of these factors include the complexity and overall size of the part as well as the process you choose to use when creating the object. Hard coat, paint, and graphic finishes will add to the lead time.

Key factors to keep in mind with 3D Printing services:

- Volume

- Footprint

- Height

- Quantity

- Complexity

- Post-processing

What is the typical price range for 3D printing?

Cost variance will greatly depend on a multitude of different factors. These factors include different machining methods, size of the object, design complexity, finishing method, quantity, and type of material used to create the part, labor cost, and how much post-production evaluation will need to be done. The overhead price for 3D printing can be costly, but the increased speed and fine detail it provides is an immense advantage over past techniques.

%202.jpg)